Facility of Positive Material Identification (PMI) to verify chemical composition of raw materials

Facility for physical & chemical testing of materials

Facility to cast single piece Cast Iron casting weighing up to 20,000 kgs

Facility to cut Stainless Steel plates of 4000 x 2000 x 20 mm thick by CNC Laser Cut Machines

Facility to cut Stainless Steel plates of 4000 x 2000 x 100 mm thick by CNC Water Jet Cutting Machine

Facility to cut Carbon Steel plates of 6000 x 3000 x 150 mm thick by CNC Plasma Cutting

Facility to shear and bend Stainless Steel and Carbon Steel plates upto 12 mm thickness.

Facility to roll plates of 3000 mm width & 30 mm thickness.

Facility to make spiral flights of 40 mm thickness and upto 5500mm diameter by CNC Flight Bending Machine.

Facility to continuously weld flights upto 5500mm dia. and 24000mm length on CNC Flight Welding Machine.

Facility to carry out SAW welding on diameter upto 5000 mm.

Facility to fabricate Carbon Steel, Stainless Steel and Aluminum products upto 30,000 kgs.

Facility to roll threads upto 100 mm diameter and upto 6000 mm length.

Facility to whirl threads upto 200 mm diameter upto 6000mm length.

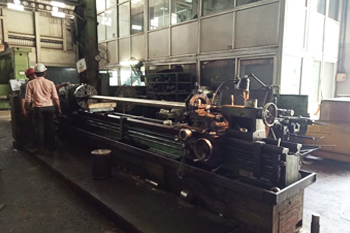

Facility to machine jobs with a maximum size of up to 7000 x 3500 x 1000mm on conventional machines

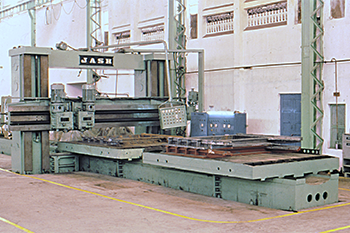

Facility to machine jobs with maximum size of up to 6000x 3380 x 1000 mm on CNC machine.

Facility to bore and mill valves upto 3600mm size on CNC floor boring machine.

Facility to bath pickle stainless jobs upto 2000 x 2000 x 6000 (WxHxL) mm size.

Facility to shot blast carbon steel products 5000 x 5000 x 20000 (WxHxL) mm size.

Facility to paint carbon steel product upto 5000 x 5000 x 20000 (WxHxL) mm size.

Facility to Hydro test sluice gates upto 6000 x 5000mm size and valve upto 3000 mm diameter.